Passive Optical Network (PON) system has expanded extensively as an optical network in the construction of Fiber To The Home (FTTH) economically. To allow multiple users to share an optical fiber in a PON, the Optical Splitter that branches an optical signal is indispensable. Recently, plug-and-play structures that make use of modules and connectors are desired to simplify the installation construction of optical splitters. Moreover, because the splitter module is installed in the outside plant, high reliability that can endure harsh environmental conditions is a critical requirement. In addition, compactness and cost savings are also important considerations. Therefore, we have developed it by economically using a superior flame-retardant plasticresin for the module case. We have confirmed that the optical splitter modules have excellent optical characteristics and sufficient reliability.

1. Introduction of Optical Splitter Modules

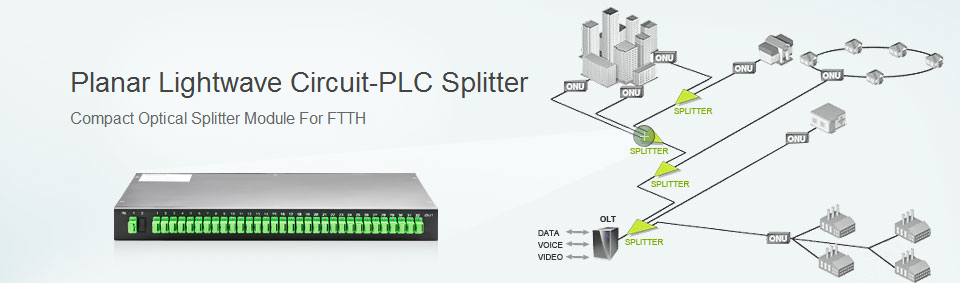

PON system has expanded extensively as an optical network in the construction of FTTH economically. As shown in Fig. 1, PON architecture allows a signal transmitted over a single optical fiber from the telephone exchange office to be shared with multiple users, hence achieving cost reduction per subscriber. Planar Lightwave Circuit (PLC) splitter, an optical splitter is a key to realize the branching of optical signal in the telecommunication network, and currently has a maximum of 32 split ratio capability.

Installation of optical splitter is simplified with the application of latch-on or snap method that can expedite the process with quick plug-in action. This plug-and-play method is commonly applied at the interconnection points in the FTTH network (This method enables field installation of optical components without any special tools or skills in managing bare optical fibers). To effectively deploy with such simple techniques and modular designs, connectorized components are essential to be integrated in the structure design of optical splitters. In addition, flexibility of network is achieved with the application of module terminated with connector cord, which allows easy reconfiguration of the network. Furthermore, in the FTTH PON architecture, the function of Fiber Distribution Hub (FDH) is to house optical splitter outdoor, therefore the FDH is critical in ensuring high reliability against environmental factors. Due to the space constraint in the FDH, down-sizing of optical splitter module design is done. The pervasive FTTH deployment worldwide has been called for an imminent need to develop low-cost solutions. The newly developed small sized and lightweight optical splitter is made from retardant plastic resin with sturdiness comparable to the conventional metal packaging in withstanding outdoor environmental conditions, but at a fraction of its original cost. This article illustrates the development of 1×16, 1×32 and 2×32 Wavelength Division Multiplexing (WDM) optical splitter module. The characteristics and reliability evaluation will also be discussed in this article.

2. Structure of Optical Splitter Modules

2.1. PLC-Type Splitter

As shown in Fig. 2, the optical fiber is being branched to 32 outputs through a 1×32 PLC-type optical splitter. PLC chip is a silica glass embedded with optical wave circuit. The circuit pattern is designed to branch a single input into multiple output channels. Optical fiber is adhered to PLC chip with resin curedby ultraviolet exposure; this interface conforms to Telcordia GR-1209 and GR-1221 test conditions, hence good reliability is ensured. Furthermore, inorder to actualize the size reduction, bend insensitive Single Mode Fiber (SMF) has been introduced into this module.

2.2. Flame Retardant Plastic Package

The structure of optical splitter module developed is shown in Fig. 3. Bend insensitive fiber with bending radius of 15 mm is applied to the optical splitter module to achieve a considerable size reduction of the packed module. The overall dimension of L118mm×D87 mm×H13 mm is 3/5 of the size of the conventional optical module utilizing SMF of bending radius 30 mm. In addition, as a flame retardant plastic resin has replaced metallic materialin the splitter packaging, the weight decreases to 1/3 of the conventional metallic packaging version.

Figure 4 illustrates the internal configuration of the optical splitter module. The splitter module is terminated with optical connector pigtails. The 2 mm fiber cords are fixed onto the cable retainer with adhesive.This structure is designed to withstand tensile strength of maximum 68.6 N. Moreover, as the optical cord has a similar structure to the loose tube cables, allowing the optical fiber free movement within the cord effects the expansion and contraction of the optical cord that will not exert any external tension onto the fiber.

The structure of strain relief boot is shown in Fig.5. The boot is designed to control the bending radius to a minimum of optical fiber limit, i.e., 15 mm. This prevents an increase in attenuation brought upon by fiber bend. The flexible boot developed has taken factors like hardness, thickness and the quantity of cord per boot into the design considerations to control the bending radius to a minimum of 15 mm when a loadis applied at 90° bend to the optical cord perpendicularly.

3. OPTICAL PERFORMANCE AND CHARACTERISTIC

3.1. Functionality of FDH

Figure 6 captures the appearance of FDH system in configuration with optical splitter module load. The hub, optical connector, and optical adapters are all mounted onto a panel to enable ease of operation with a latch mechanism. The pigtail is elegantly managed in a U-shape through the mandrel. This plug-and-play method makes installation extremely simple and efficient.

3.2. Fundamental Optical Characteristics

The 1×16 and 1×32 splitter modules were fabricated to be mountable onto the above described fiber distribution hub. The vacant port (a port which is not in service) present in the FDH will result in back reflections of the optical signal. To prevent return loss from the end face of vacant port, SC connector is polished to an Angled Physical Contact (APC) interface. Data below tabulates the optical characteristics of the optical splitter module, inclusive of the connector pigtails.

The histograms shown in Figs. 7 and 8 illustratethe insertion loss performance of 1×16 and 1×32 optical splitter module respectively. At operating wavelength 1310 nm, the average insertion loss of 1×16 splitter stands at 13.23 dB while that of 1×32 splitter is 16.33 dB. Similarly, at 1550 nm operation wavelength, the insertion loss of 1×16 and 1×32 splitter module is 13.10 dB and 16.22 dB respectively. In addition, the standard deviation of 1×16 splitter is 0.29 dB while 1×32 splitter yields a standard deviation of 0.34dB. At the same time, this value decreases to 0.23 dB for 1×16 splitter and 0.28 dB for the 1×32 splitter at wavelength 1550 nm.

The performances of other optical characteristics apart from insertion loss are shown in Table 1. These results show consistent good performances, as exhibited in the insertion loss histogram, in characteristics including uniformity, return loss and PDL values.

3.3. Temperature dependent loss

History from past experimental results has shown that components terminated with optical pigtail cord are susceptible to insertion loss fluctuation with temperature change. To isolate the effects of cordage expansion/contraction on the optical fiber within, the optical cord is designed to allow free movement of optical fiber, thus eliminating the external stress fromthe expansion/contraction of the cord. Figure 9 depicts the insertion loss variation of the 1×32 optical splitter module during temperature cycling from −40 °C to +85 °C. The average, minimum, and maximum values obtained from the 32 output ports are illustrated in the graph shown in Fig. 9. From the graph, the maximum loss deviation between the ports with maximum and minimum insertion loss is 0.17 dB. This result has an evident exceptional stability of the optical splitter module that is developed.

3.4. Wavelength dependent loss

The wavelength dependent loss of the 1×32 optical splitter module is shown in Fig. 10. The performances of insertion losses over wavelengths from 1260 nm to 1680 nm are measured. Again, the average loss from 32 ports and minimum and maximum wavelength dependent losses are illustrated in the graph. The average deviation is 0.36 dB while the maximum deviation from all the 32 ports is 0.86 dB.

This proves that the splitter module has shown resilience in insertion loss variation over a broad spectrum of wavelength.

A variety of optical devices are stored in this optical splitter module, making it multifunctional. An example is the 2×32 WDM optical splitter module shown in Fig. 11 and the structure of its cable retainer in Fig.12. A WDM filter was built in front of a 1×32 splitter module, enabling the structure to have multiple wavelengths.

Figure 13 shows the wavelength dependent loss of the 2×32 WDM optical splitter module. With the WDM filter, the wavelength ranging from 1530nm to1570nm are transmitted from the B port, and the other wavelength ranges are transmitted from the A port. The wavelength dependent loss of A port and B port are split evenly among the 32 fibers, hence excellent loss performance is obtained in each port.

4. Reliability of Optical Splitter Modules

The reliability of 1×32 splitter module is evaluated in accordance to test procedures stipulated in the Telcordia GR-1209 and GR-1221. The test conditions and the results of the 1×32 splitter module measured at 1550 nm are shown in Table 2. The average, maximum, and minimum values of 32 output ports measured are recorded in Table 2. The results of side pulltest and cable retention test are maximum in-situ datamonitored during load application onto the cable cord. On the other hand, the recorded data of damp heat, temperature cycling, mechanical shock, vibration, and water immersion shows the variation of insertion loss before and after the test conditions. From the results, it is confirmed about the reliability of 1×32 splitter module.

The results of high temperature and humidity test are depicted in Fig. 14. The optical splitter samples underwent a total of 2000 hours of storage at 85 °C and of 85% relative humidity. Insertion loss data at 100 hrs, 168 hrs, 500 hrs, 1000 hrs, and 2000 hrs juncture were measured. The average insertion loss of the 32 ports, maximum and minimum insertion loss measured at 1550 nm are displayed in the graph. From the graph in Fig. 14, it is concluded that there is very minimal loss variation even after 2000 hrs. The optical splitter module has shown good stability when exposed to high temperature and humidity conditions.

Furthermore, to meet the flame retardant requirements for optical components and accessories, we have applied frame retardant plastic material of 1.5 mm thickness complying to UL-94 V-0. On the same note, the jacket of optical fiber cord is made of grade V-0 flame retardant PVC.

5. Conclusion

A compact and economical optical splitter that boasts of superior optical performance and reliability against stringent environmental conditions suited for outdoor installation has been successfully developed. This plug-and-play design for installation of the above optical splitter has enabled simple and speedy installation, at the same time provided added flexibility for future network reconfigurations, thus making this optical splitter module the perfect solution for PON architecture FTTH deployment.

There is always at least one dead zone in every fiber—where it is connected to the OTDR. The existence of dead zones is an important drawback for OTDR, specially in short-haul applications with a large number of fiber optic components. Thus, it is important to minimize the effects of dead zones wherever possible.

There is always at least one dead zone in every fiber—where it is connected to the OTDR. The existence of dead zones is an important drawback for OTDR, specially in short-haul applications with a large number of fiber optic components. Thus, it is important to minimize the effects of dead zones wherever possible.